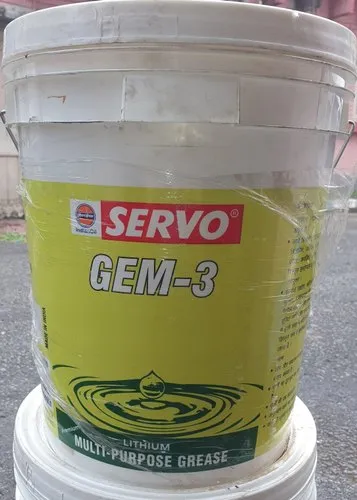

Servogem 2 and 3 are multipurpose greases recommended for anti-friction and plain bearings lubrication. Servogem 2 and 3 meet the requirement of British Timken ALG bearing 1/57, IS: 7623-1993 (Second Revision) Reaffirmed 2001, IPSS:1-09-006-1997 specifications and U.S. Steel 374 requirement. These greases are widely used in steel plants, heavy engineering units, textile mills, petrochemical and chemical units etc.

Application

Servogem EP greases possess extreme pressure (EP) properties and prevent welding and seizure of moving parts often caused by shock loading. Servogem EP greases meet IPSS: 1-09- 005-1999 and IS:: 7623-1993 (Second Revision) Reaffirmed 2001, specification. These greases are recommended for both plain and antifriction bearings in a wide variety of pplications such as automotive, earth moving equipments, gear couplings, electric motors, mining equipments and general industrial machinery. Servogem EP 2 (C) grease is a lime base grease developed to meet the IPSS 1-09-009- 1997 requirements. The product is suitable for lubrication of severely loaded bearings at a temperature of (-) 20 to +650C where ingress of water cannot be avoided. Servogem EP 0(N) has better water washout resistance and higher antiwear properties. Servogem EP 2(S) has superior thermal and oxidation stability and resistance to water washout.

Physico-chemical properties

| PRODUCT | Kin. Viscosity cSt at 40 °C | VI Min. | Flash Point COC, °C Min. |

| Servospin 2 | 2.0 – 2.5 | - | 70 |

| Servospin 5 | 4 – 5 | - | 70 |

| Servospin 10 | 9–11 | - | 144 |

| Servospin 12 | 11–14 | 90 | 144 |

| Servospin 22 | 20–24 | 90 | 160 |

| Servospin EE 10 | 9–11 | 90 | 144 |

| Servospin EE 22 | 20 –24 | 90 | 160 |